In a competitive business like construction, the quality of work that you provide your customers, is an important differentiator for your business.

Hence, Quality Management – Quality Assurance and Quality Control – is a very central to a construction project.

Construction contractors must take quality management more seriously when their business starts to grow. This is the time when the team grows bigger with new people joining in. This is the time when quality goals should be defined for the organization and procedures must be set in order to ensure those goals are met.

This is also when contractors realize how standardization of work practices will help in improving the quality of their work.

Once you have defined your quality goals and decided to bring more standardization, how do you actually go on achieving it?

Here’s a notional checklist for construction contractors to standardize their work practices –

1. Documented Procedures for Quality Assurance

One of the objective for standardization of your work is defining a uniform idea of quality for all team members and project stakeholders.

Different people have different idea of quality. For example – a design engineer’s idea of quality can be very different than what a mason on site thinks about construction quality.

A standard document for quality management will define the common quality goals to be achieved by the team. So that every team member will have the same understanding of what quality means.

The same standard documents can also outline a roadmap for achieving those quality goals and further still, establish detailed standard procedures adhering to this roadmap. When these documented procedures are followed by all team members, quality assurance can be guaranteed.

But how to ensure that all team members stick to these documented work procedures?

2. Quality Assurance (QA) Training

First important step is to provide adequate training to ALL team members who will be involved in relevant construction activities.

Merely creation of a document for standard work practices does not ensure that all team members have read the document and understand it. That will have to be made sure of via proper training.

The goal of this quality assurance training would be to –

- Educate all team members on the standard work practices which have been documented.

- Make sure that they have understood what steps they need to follow – may be via a short quiz afterwards.

- Get feedback on the documented procedures and incorporate suggested improvements.

After your team has been educated about the new procedures, you also need to make sure that they get into a habit of following those procedures.

Building habits is not easy, since it needs your team to change their behavior. But technology can help you and your team to get habituated.

3. Digital Workflows

Digital workflows can be very effective for implementing the standard QA procedures to be followed.

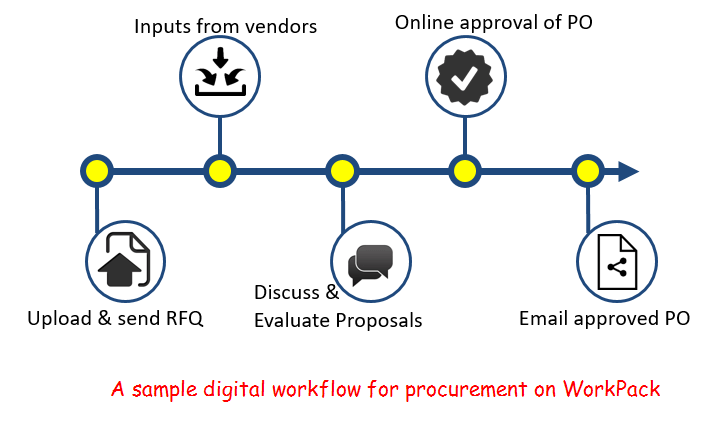

The procedures can be configured as steps in a digital workflow which have to be completed in order to complete any construction activity – much like a QA checklist.

If your team members MUST follow these steps, over time they will build a habit out of it.

To make it easier for the team members to follow these digital workflows, they can be used to connect the tools of daily use, like – emails, spreadsheets, mobile apps, shared document folders etc.

If you can correctly replicate your actual work procedure in a digital workflow, your project team need not worry about a changing their work habits. They can go on sending emails, updating spreadsheets, sharing documents – as they are already doing. And the digital workflow will record and monitor all their actions now connected via the workflow, to ensure they have followed the correct steps.

4. Central Communication Platform

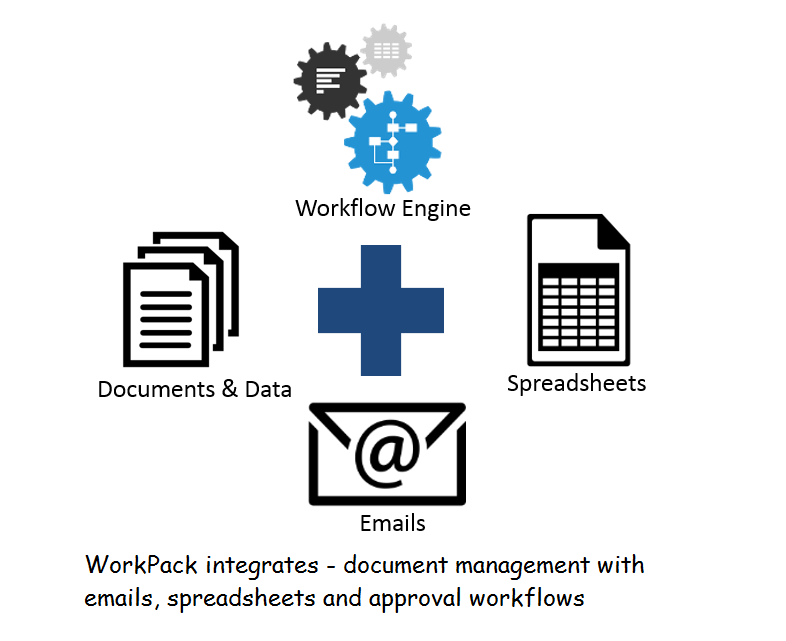

Apart from connecting your favorite digital tools, it is also important to integrate all of them on a single digital platform.

Otherwise, when you work separately with spreadsheets, emails, document storage etc, there is no easy way to know whether you have followed the correct procedure.

A central digital platform with all important tools, will enable you to track ALL the actions taken by your project team. A digitally integrated system will have minimal number of blind spots or loopholes if any.

For quality assurance, you want to minimize these loopholes as much as possible.

5. Easy Access

To ensure that your project team follows your digitally configured workflows, you must ensure that all the involved digital tools are easily accessible to every team member.

If they are not, people will look for ways to bypass your workflows and by doing so they will bypass the standard procedures you have set up for QA.

Wider access can be enabled by using a cloud based system for digitizing your processes. Cloud systems are cost effective and can be accessed by your own team as well as any external stakeholders.

Next, accessibility to each and every team member can be ensured by connecting mobile apps to your cloud based system. So that members on the site can also easily access the standardized digital workflows.

Using WorkPack for Quality Assurance

WorkPack is a project management platform trusted by managers of construction projects across different industries.

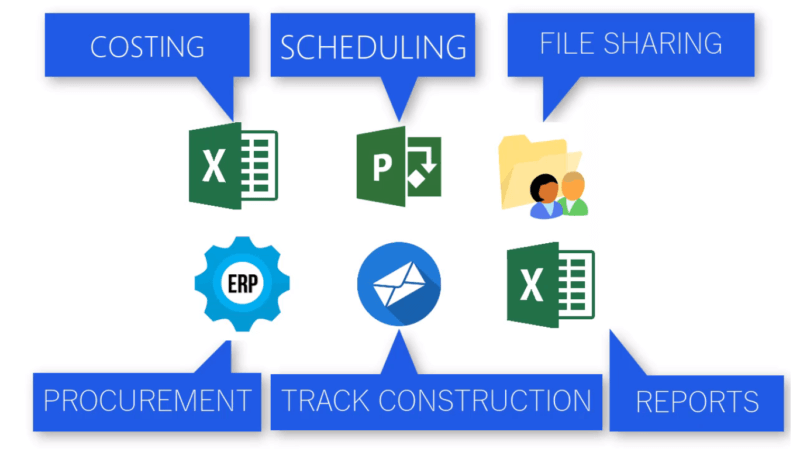

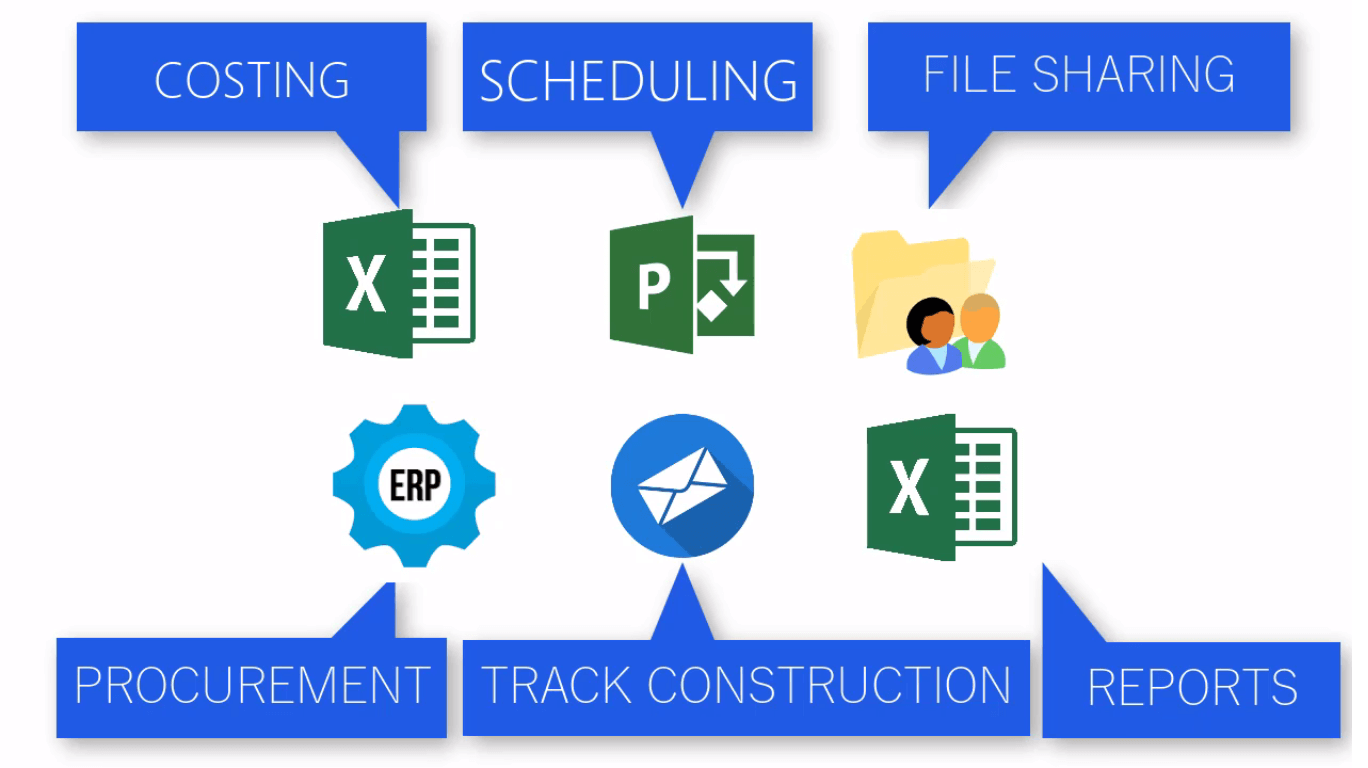

It connects your favorite tools of day to day work on a central platform, equipped with digital workflow engine.

WorkPack thus checks all the boxes for being the perfect construction management solution, even from a QA point of view.

Do you think it will be a good fit for your project team? Find out by signing up for a free trial.

Let us know in case you want to schedule an online demo and check out how it works.

No Comments