If you work in the construction business, you know it’s quite competitive. One of the ways in which you can differentiate yourself and win over your competition is by ensuring top notch quality in all your projects.

But what do we mean exactly, when we say quality?

Quality of your construction work usually depends on a number of factors –

- Meeting technical specs as per the contract

- Finishing the project before schedule

- Keeping the costs within budget

- A smooth work history without disputes

Why quality is important in construction

All these factors which reflect into quality are primary indicators of good work done by a construction team. The idea of quality clubs them all together.

Since the idea of “quality” is an aggregate of all these important factors by which we judge how good the construction work is, naturally it is a very important factor in a construction project.

Ensuing good quality of construction is one of the most important responsibilities of a construction project manager.

To achieve high quality of work, a manager has to set common goals for the team to meet certain quality standards and then motivate them towards those goals.

Setting up uniform goals for quality

But, the concept of quality is not the same for everyone on the team. For example – a design engineer’s idea of quality can be very different than what a mason on site thinks about construction quality.

Without a uniform understanding of quality, setting up a shared quality goal is going to be difficult.

An answer to this lies in formally standardizing your construction work practices.

This can be done by documenting the standard work practices, processes to be followed for different types of activities.

Once a common objective is defined, there are two possible approaches to achieve that goal

- Quality Assurance (QA)

- Quality Control (QC)

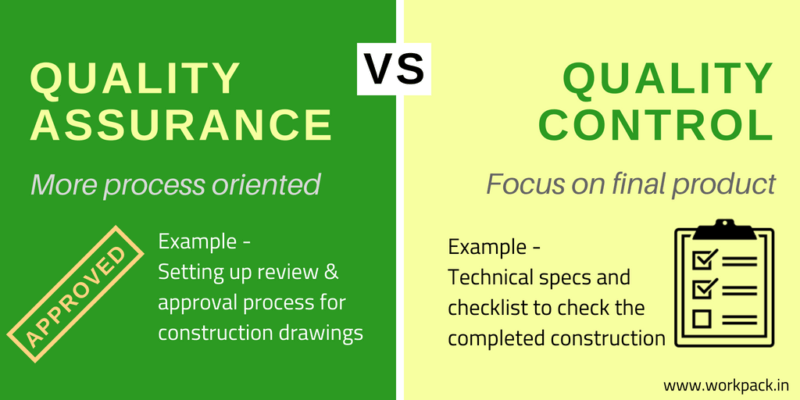

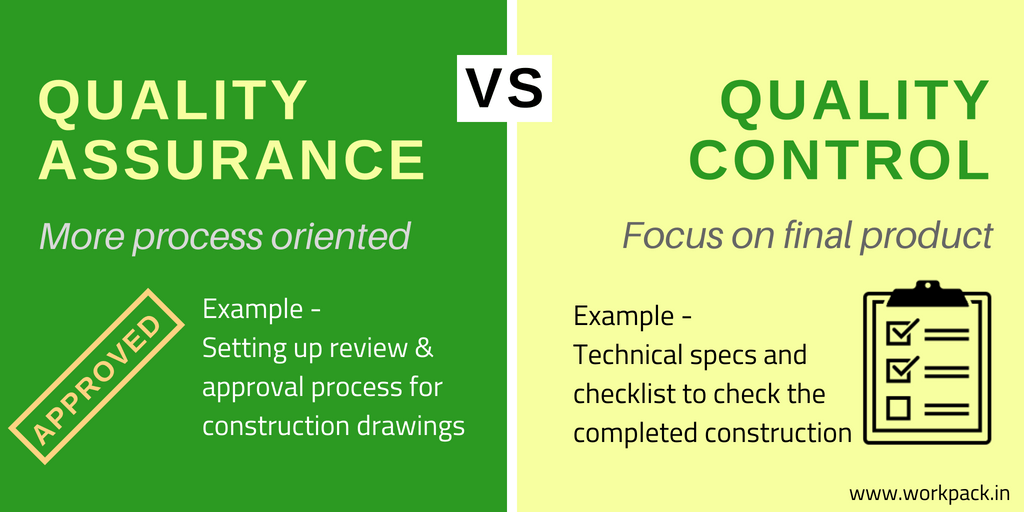

Both of them are meant for achieving good quality construction work and they have a lot in common. But even then, there is a basic difference.

Quality Assurance (QA)

Quality Assurance (QA) is normally more process oriented. It involves monitoring the work processes to ensure that they will produce good quality in final product.

For example – in context of construction projects, Quality Assurance on the Engineering Consultant’s side involves, setting up a review and approval process for all construction drawings before they are issued for construction on site.

This process is usually set up by the Engineering Consultant and audited by project managers or QA managers from the project owner’s side.

Adherence to standard processes is important in case of Quality Assurance (QA).

Quality Control (QC)

On the other hand, Quality Control (QC) is more focused on the end product.

In case of a manufacturing business, a QC manager would normally do random quality checks on the product to ensure that they meet the required technical specifications.

In case of construction projects, a QC manager would survey the actual construction taking place on site, material used, pace of work, adherence to schedule etc.

Technical Specifications, Inspections, Quality Checklists etc. take the center stage in case of Quality Control (QC).

Importance of QA / QC

We already saw why it is very important to maintain high quality of work in a construction project.

Moreover, maintaining quality becomes a bigger challenge when a construction business starts to grow. In such cases, construction project managers need reliable ways to achieve a certain level of quality in their projects.

We are more likely to achieve these quality targets, if the actual quality is monitored, measured and improved on regular basis.

QA and QC are exactly the tools needed to do this.

2 Comments

geoq

September 22, 2020

quality assurance and quality control are in the same field as it is very important on a large construction company like this.

John Moss

November 3, 2020

“Ensuing good quality of construction is one of the most important” I totally agree with this statement of yours and I want to focus on quality training. Our company always see to it that we provide such quality training and each personnel has white card gladstone before they can work in the construction industry. Quality in three areas, your people, your management, and the supplies.