Kanban is a method for streamlining supply chain for lean manufacturing. It originated in Japan and it literally means a ‘signboard’ or ‘billboard’ in Japanese. So Kanban is actually a visual board which summarizes the status of work being done.

How a Kanban board works

First, all the work to be done is broken up into tasks. A Kanban board then captures status of each task as it moves through different stages. In the most basic form, a Kanban board will capture tasks moving through following stages – To do, Doing and Done.

All tasks to be done are written on cards. The cards (tasks) to be done first, are placed in the ‘To-do’ column. The team can see the pending tasks and select what to work on. As the work gets done, task cards they are moved to ‘Doing’ or ‘Done’ columns.

New tasks are added to the ‘To-Do’ column as and when people are free to attend to them.

Visual simplicity of Kanban

Very simply, one look at the Kanban board will tell you what is pending, what is being worked on right now and what you have already completed. Visually it then becomes very easy to read and to quickly understand the exact status of work.

Flexibility in Kanban

You can simply add more columns to a Kanban board if you want to track more stages in a task than – to-do, doing and done. That makes the Kanban board flexible and easy to manage.

For example, in case of rooftop solar projects following stages can be used to construct a Kanban board that enables easy monitoring of project execution – Awarded Projects, Engineering Design, Material Purchase, Installation, and Commissioning.

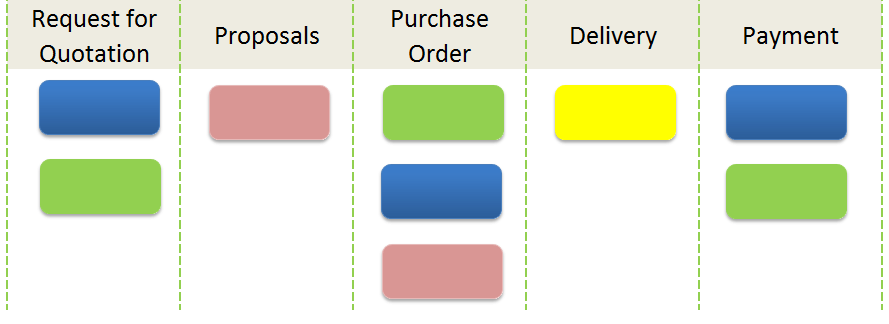

Or in case of a procurement tasks, you can have following task level stages to monitor – RFQ, Proposals, Purchase Order, Delivery and Payment.

In both cases, a Kanban board can help you to easily keep track of multiple ‘projects’ and many ‘procurement tasks’ respectively.

How Kanban can highlight the bottlenecks

The number of cards (tasks) in a Kanban board column indicate the bulk of the work getting stuck in the process, at the time.

For example, consider the case of Kanban board for procurement from above. When you see relatively many cards (tasks) at ‘Purchase Order’ column compared to others, it means PO approval and release is becoming a bottleneck in the procurement process. Subsequently, you can either try to make the approval process smoother (e.g. opt for electronic approval) or use more resources for approval (delegate to senior buyers).

Kanban is thus able to point out and highlight the bottlenecks in how you are running projects. And problems can be fixed only after you are able to see them. So this visibility is crucial for streamlining projects in a dynamic environment.

Well suited for dynamic work environment

Rooftop solar projects are quite dynamic in nature. Usually, they are fast-tracked projects with a smaller scope of work, to be executed by lean execution teams.

To successfully manage these dynamic projects, you need to keep an eye on how they are moving. So that you can spot any bottlenecks and resolve them before they damage project schedule. Kanban will help you to do exactly that, as we saw in the example above.

WorkPack for Kanban

You can use a physical whiteboard for a Kanban board. But electronic systems can offer far more depth and traceability of information than what can even be possible with a whiteboard.

And there are multiple e-Kanban systems available in the market as well. But they are not quite wired for solar power projects.

WorkPack dashboard works on the basis of Kanban principles and is specifically configured for solar projects. So whenever you log in, you will see how your multiple projects are moving through the different stages of execution.

You can also see how different tasks of those projects are moving on the same dashboard.

![]()

Based on the Kanban principle, WorkPack enables you to see items (projects or tasks) moving through different stages. WorkPack uses circles instead of cards in columns so that you can also track history of project execution.

Further, you can click on any circle to check where a particular stage of project execution is getting stuck.

For example, if you click on ‘Purchase’ stage circle, you will see which of the items from project BOM are still pending for procurement. This gives you the depth in information that cannot be achieved on a Kanban board.

All the while user interface is as simple to understand as a whiteboard. That is why solar rooftop installers are now replacing their whiteboards with WorkPack dashboard.

If you are wondering if WorkPack can also help your solar project team with execution, check out how it works. You can also sign up for a free account to test drive the WorkPack dashboard. Let us know in case you have any questions or need any help to get started.

No Comments