The recently concluded annual meeting of the World Economic Forum in Davos, highlighted possibly the biggest inflection point in technology and commerce in the recent times – the ‘4th Industrial Revolution’.

The recently concluded annual meeting of the World Economic Forum in Davos, highlighted possibly the biggest inflection point in technology and commerce in the recent times – the ‘4th Industrial Revolution’.

Industry 4.0

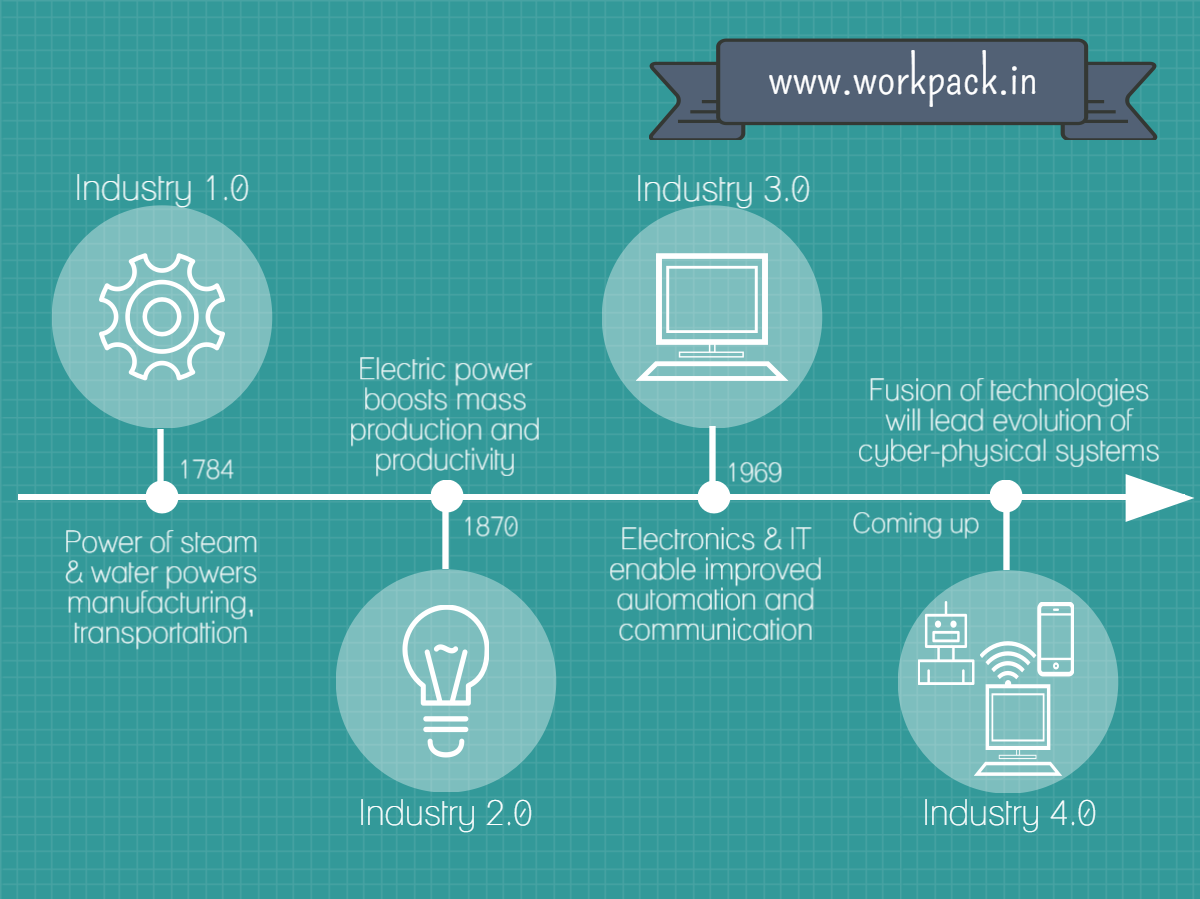

- First industrial revolution was triggered by invention of the steam engine in 1780s. Steam and water power then drove the explosive growth in output by mechanized production.

- During the second industrial revolution, electric power began to be transmitted over distances. Electricity replaced steam and water to drive mass production, driving industrial outputs to new levels.

- Since 1970s, usage of electronics, information technology and digital technologies in businesses has been driving further revolution in productivity – the third Industrial Revolution.

- Now a fourth Industrial Revolution or Industry 4.0 is building on the third digital revolution. This change is characterized by a fusion of factors – ever growing connectivity of internet & mobile, unprecedented processing power, artificial intelligence, human–machine interactions, massive and easy availability of data and knowledge.

Man & Machine

One important change caused by this impending industrial revolution may be the increasing dependency between man and machine.

As per Klaus Schwab – the founder of WEF – “Already, artificial intelligence is all around us, from self-driving cars and drones to virtual assistants and software that translate or invest. Impressive progress has been made in AI in recent years, driven by exponential increases in computing power and by the availability of vast amounts of data, from software used to discover new drugs to algorithms used to predict our cultural interests.”

Automation and artificial intelligence will increasingly drive improvement in business processes. Some industries are already seeing the new technologies disrupting their long established value chains.

WEF surveyed executives from information and technology communications industry, to estimate the risk of automation of jobs across different industries. Findings suggest that for half of the major industries, more than 55% of the jobs are at the risk of being automated by 2025.

Engineering & Construction Industry

An average employee in the engineering & construction companies relies heavily on – specialized skills, vertical specific experience, technology training, technical knowledge & judgment – things that are extremely difficult to automate.

Also engineering & construction industry is a project intensive industry. Most of the work is project specific and hence changes from one project to another.

These facts are also reflected in the findings from WEF survey, suggesting that risk of automation for engineering & science jobs remains below 15-20% range. What the numbers from this survey suggest is a big wave of changes.

Engineering jobs will most likely not be completely automated. But instead machines will be increasingly more helpful to people for doing more with less. Construction industry has been changing for centuries and getting better with each technology revolution.

- The book-keeping functions of project coordination will likely get easily automated with an integrated set of software tools

- Availability of past project data will bring new insights and learnings to improve project execution practices

- Increasing connectivity between people and devices will boost overall visibility for projects

- Robots will be able take up the riskier work in construction, improving safety at work

- Overall some jobs which are repetitive and streamlined in nature will be taken up by automation

Again in words of the WEF Founder, “As automation substitutes for labor across the entire economy, the net displacement of workers by machines might exacerbate the gap between returns to capital and returns to labor. On the other hand, it is also possible that the displacement of workers by technology will, in aggregate, result in a net increase in safe and rewarding jobs.”

Challenges & Opportunities

For infrastructure industry there will be quite a few challenges as machines take up some work

- Ensuring quality and compliance – Quality and compliance needs may change from one project to another. Machines will need to adapt under different environments and requirements

- Managing experience – Traditionally the industry has always given a lot of importance to experience. Managing a force of artificial workers with little prior experience will be challenging. Machine learning and heaps of past project data might provide answers.

- Competition – executives from different industries are already feeling the winds of upcoming industrial revolution. Companies will need to adapt with the evolving technologies to maintain their competitive edge.

Organizations who successfully meet these challenges will be rewarded in the end, as the changes will also bring opportunities with them.

- Shake up the value chain and become cost effective with usage of technology. Beat your competition.

- Effective usage of technology by the workforce has potential to radically improve productivity and delivery time

- Overall it is possible to make working in the construction industry more rewarding and satisfying by getting machines to help us.

1 Comment

Aman Moudgil

July 8, 2020

While i agree on the advantages induced through mechanizing the construction processes both for the Principal employer and the Management team as involved, I see digitization and technology as a very good tool in imparting efficiency to the overall management and handling of the project, however, human wisdom (which is highly needed to handle untoward situations on ground) cannot be digitized completely.